Cleaning of reflectors and fixtures

Optimizing growth light by cleaning

To achieve the best light output we proceed as follows:

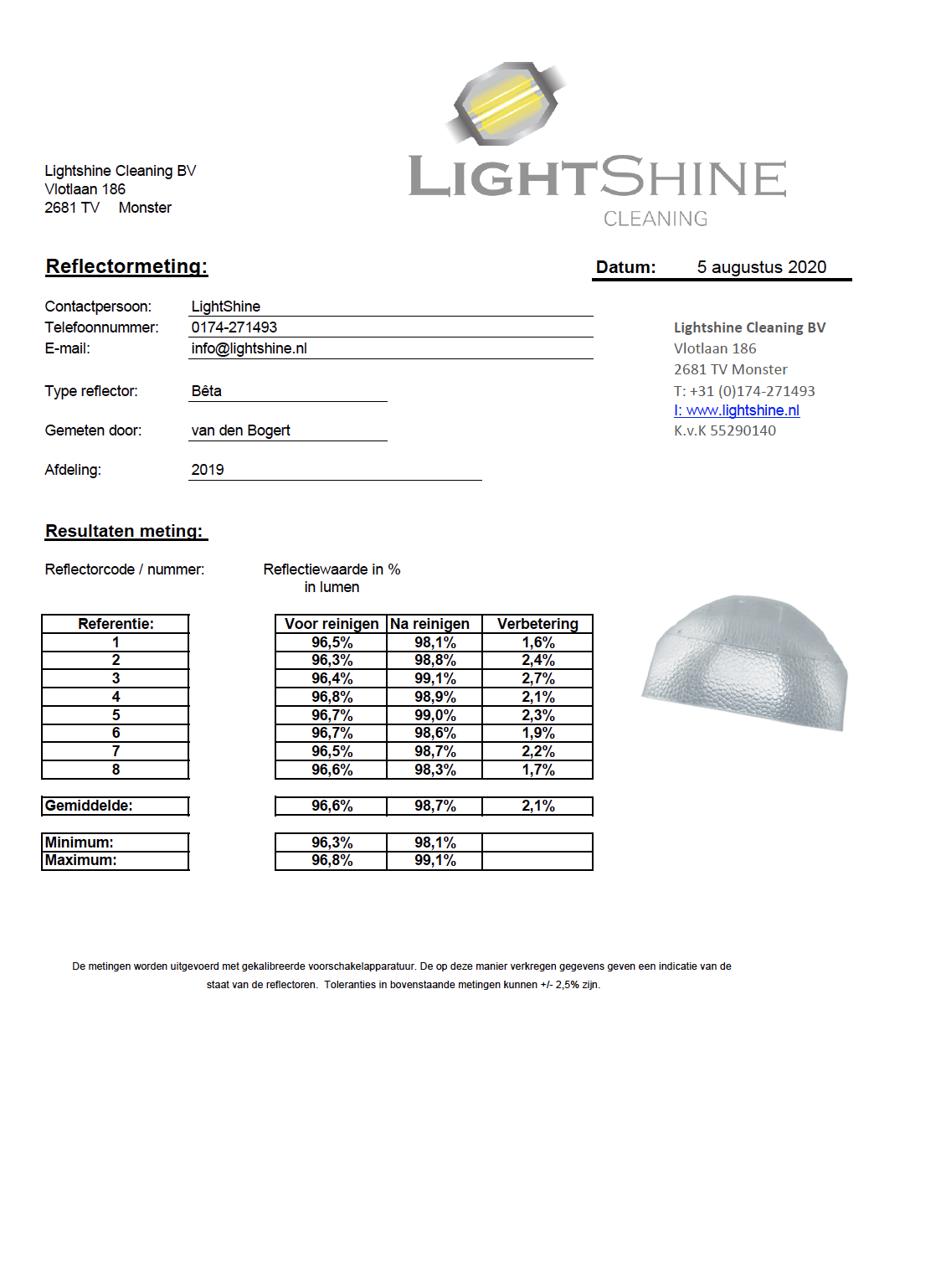

In addition to the price request, you can opt for a zero measurement or trial measurement. Such a trial measurement helps to give you a realistic picture of the possibility to optimize the supplemental lighting. By gaining insight into this result, you can take informed action. You can then choose whether to have the cleaning performed at your location or at LightShine. The process is tailored to your choice of location. Finally, a result measurement is done where demonstrable difference is made known to you through an expert measurement report.

Want to know how much profit you can make by cleaning your reflectors and light bulbs? We calculate your current reflectance and light output and the expected light output after cleaning. So you can make an informed decision.

Result awareness through expert measurement report

LightShine Cleaning has a measurement laboratory for preparing expert measurement reports. By performing an accurate test measurement, we can show with clear figures exactly what the current light reflection is and what it will be after cleaning. We ask that you provide some of your reflectors and possibly from different departments, so that we can make a good baseline measurement. You will know exactly how much profit cleaning the reflectors will give you.

Location choice

Due to hygienic considerations, 90% of the cleaning takes place on the customer’s site. For this reason, the mobile cleaning machines are also fully decontaminated at all times after each use. A major advantage of cleaning on site is that the reflectors can be immediately re-hung. The only conditions we set for this is that our cleaning machine can be connected to tap water and that a power connection is available. In addition, you can also choose to have LightShine Cleaning carry out all additional work; the well-known ‘unburdening’. This means that not only the cleaning of the reflectors is done by us, but also the disassembly and reassembly of the caps after cleaning. This allows us to offer you a complete service with minimal disruption. In some cases the customer wishes to have the cleaning of the reflectors not done on site, but at LightShine Cleaning itself. This is of course no problem at all. The only thing I have to give you extra consideration is the transport of the reflectors and the fact that the reflectors are disassembled for a longer period of time.

Execution of cleaning reflectors and fixtures

Implementation is tailored to your choice of location